|

Plug Feed

and Check System - Vibrating Bowl Feed & Laser Measure

To meet the demands of 100% checking and inspection

requirement that are becoming standard within the automotive industry,

TQC designed and manufactured a standalone machine for the automatic

feeding and checking of an automotive plug.

Utilising an elevating hopper and vibratory

bowl feeder to accept bulk product and orientate each plug, a laser

measurement system is incorporated to check a feature on the product.

The plug is transported through the machine using a walking beam

and the part is rotated a full 360 degrees.

The automotive industry based customer required

a 100% check to ensure that a continuous bead of thread locking

sealant is the correct thickness and continuous round the flange.

The system accommodates a single size

of stud at any one time, but is adjustable for sizes from M10 to

M20, the overall throughput was 20 studs per minute.

|

|

|

|

|

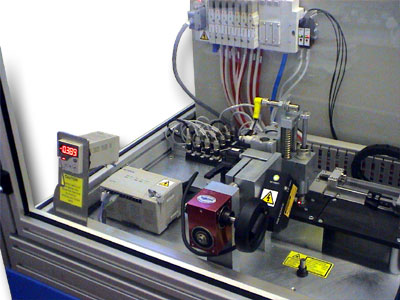

Fully

Automatic Feed and Inspection System

for Automotive Plugs |

Elevating

Hopper

Fed Product |

Inspection

/ Dectection

Station

|

Keyence

Laser Sensor

for Inspection |

Key Elements

- Elevating Hopper & Vibratory Bowl Feeder

- Laser displacement measurement system

- Walking beam transfer system

- PLC Control

|