|

Pallet

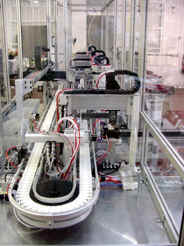

Based Assembly System for Plastic Parts

TQC have performed a number of sophisticated

pallet based automatic assembly and test projects for several demanding

applications. The system shown here was designed and engineered

for the automation of a glove box latch assembly for a high volume

automotive manufacturer. The latch can be produced in different

formats for different applications, hence a modular automation approach

has been adopted. The production volumes are large and hence the

machine cycle time is relatively short. The system was supplied

to Southco Manufacturing winners of the Management Today 2001 Best

Factory Award.

TQC have provided multi station industrial automation

production lines and robot workstations in different applications,

ranging from automotive parts manufacture, transfer of green state

ceramic components, medical device assembly and precision automation

at high speeds.

|

|

|

|

| Fully

Automatic Assembly System using Multiple Stations for Sequential

Assembly |

Plastic

Parts Bowl Fed |

This particular assembly cell is engineered to

have minimum operator involvement. All parts are automatically fed

from vibratory bowl feeder systems where box quantities of product

are loosely tipped into the feeding bowls.

The output from the cell is automatically placed

into shipping cartons at the unload station.

The system takes six parts, including plastic

mouldings and springs to assemble the latch. The part is tested

for correct operation within the cell after the assembly operation

is complete. The good parts are automatically ink jet marked.

The facility is completely guarded with aluminium

extruded frames and clear guard panels. All of the openings for

the bowl feeders are outside the guarded area, allowing the operator

to top up the bowls without stopping the machine. The deposit point

for the assembled and tested product is also outside of the guarded

area. The carton filling system also has an automatic carton change

facility.

The production line has been engineered to allow

for future variants of the similar high volume automotive latch

mechanisms to be assembled on the same production line. The design

of the assembly cell follows a modular approach; each element is

wired and piped back to distribution points on each station.

The system incorporated a PLC control system

complete with Human Machine Interface Panel. The HMI unit consisted

of a display and function buttons, this was used to provide status

information on the machine for diagnostic purposes and manual setting

operations at each station.

Attention was paid to minimising noise levels

on the shop floor by using acoustic covers. In addition, there was

a roof on the guarding system over the pallet conveyor area for

additional noise reduction and to keep the whole system clean.

Similar systems have been engineered by TQC

to assemble a diesel fuel switch, a distributor and domestic appliance

switches.

TQC used it’s professional engineering

project management approach to ensure that this project met both

timescale and budget requirements.

TQC welcomes the opportunity to design and

manufacture complete automation systems to client specifications.

Contact our Engineers to advise you on your automation project.

|