|

Rotary Machines

& Systems - Assembly & Testing

Rotary assembly machines are used extensively

in fully and semi automatic assembly and test.

The advantages of using an indexing or continuous

motion dial plate with a series of fixtures are the relative low

cost and rapid index of the transport system.

Fully automatic systems can reach throughputs

of 400 a minute or more when continuous motion is used. The use

of a rotary assembly and test machine is advantageous when the cycle

time is greater than 5 seconds and an operator is best used for

some of the assembly processes.

The operator can be used to position difficult

to feed parts into the fixtures or used as a final inspection operation,

or both.

Rotary or carousel type assembly machines can

also offer a compact form of semi automatic machine. The nest tooling

tends to be “dumb” because of the continuous rotation.

The assembly and test tooling is usually arranged in a radial fashion

secured outside of the dial plate. Twin or even multiple track nests

are possible, as are interchangeable nests for different variants.

TQC have considerable experience in engineering

rotary assembly machines, combining sophisticated test and assembly

on the same machine.

|

|

|

|

|

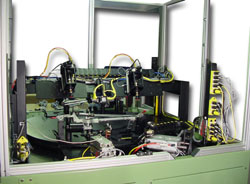

Semi-Automatic

System

with Spin Rivetting

|

8-Station Machine

|

Function

Testing of Automotive Wiper Assemblies on a 2-Station Machine

|

Front

Manual Load/Unload Station,

Rear

Test Station

|

Rotary Machines & Systems typically incorporate the following

modules

-

- Operator load station

- Press station

- Orbital spin riveting

- Automatic electro-mechanical testing

- Automatic labelling Vision system

- Automatic glue or sealant dispensing

- Vibratory feeding

- Robot modules

Typical applications

Automotive part assembly Medical device assembly

Automatic electro-mechanical test Automatic leak test Simultaneous

assembly and test Dual or triple track assembly

If you have an assembly and/or test requirment

and need equipment, please contact TQC.

|