|

Assembly

Cell & Robot Cell Solutions

TQC have recently performed a number of sophisticated

robot cell systems for several demanding applications. The projects

have ranged from the use of proprietary robot units to the development

of a large, complex gantry robot system.

TQC have provided multi robot production lines

and single robot workstations in different applications, ranging

from automotive parts manufacture and modification, transfer of

green state ceramic components to high precision automation at high

speeds.

One significant project involved designing several

single robot cells to automate the assembly of a small electrical

handset. An operator loads the bottom casing (containing the

PCB) and top casing into the jig section within the assembly cell,

which then automatically closes, clipping the two parts of

the handset together. In this assembly

cell the robot picks four screws from the bowl feeder and drives

them into place in the handset, one at a time. This machine

cell produces a complete handset every 12 seconds. The complete

robotic production system incorporated four robot cells.

A more bespoke application TQC supplied was

for a facility that had a working envelope of 6 meters x 4 meters

x 2.5 meters. The end effector (gripper) was specially designed

to transfer delicate "green state" ceramic components

together with 3 other parts and assemble. The gripper transfers

12 items at a time stacking them accurately onto a surface of varying

heights & attitude. This system incorporated

a reconfigured robot unit. The drawing to the right, shows the new

configuration of the main elements. Associated with this unit is

a pallet magazine, multiple transport conveyors and an elevation

unit bringing product from a level 4 metres above. TQC

was responsible for the successful integration of the complete system

including the designing of vacuum formed trays and other product

storage.

Both of the above systems were integrated into

factory wide SCADA systems on an Allen Bradley platform.

TQC welcomes the opportunity to design and manufacture

complete automation systems to customer specifications.

|

|

|

|

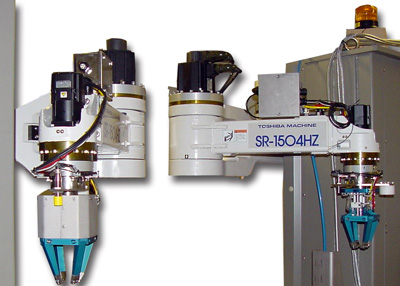

Robot

Controlled

Screwdriving Operation |

SCARA

Robot

central part of Handling Line

|

TQC

are a Kawasaki Robotics

System Partner |

Key Benefits for Assembly Cell / Robot Cell Supply

-

- Professional &

Flexible approach to all engineering tasks bestowed upon us

- All work completed

in house - so the buck stops here!

- 24 hour Customer

support, backup and service call-out for all projects large

and small .

Production

Equipment

TQC's

production line and mechanical handling equipment can be integrated

with automated online test equipment for use in any manufacturing

industry, including the food, brewery, automotive, consumer and

pharmaceutical industries.

Each TQC

unit is designed to provide the best solution for reducing labour

costs, increasing output and eliminating manual handling concerns.

Whether your

production facility needs a simple bench top system, a more complex

upgrade of your existing equipment, or a fully integrated production

unit, TQC are able to provide a complete solution with a professional

approach.

If you have a current

project that you are already looking at, or you are considering

improvements to your production in the near future, call us and

we will be happy to offer our professional advice & visit you

at your site

|