|

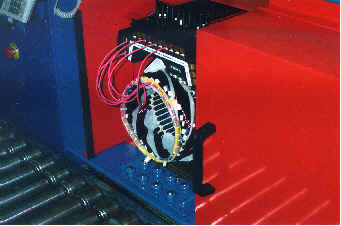

Motor

Stator Testing - Resistance / Inductance / Flash / Rotation

TQC has specialised in automated testing of electric

motor stator windings and fully assembled motors for many years. Equipment

has been developed in conjunction with several manufacturers to maximise

the benefits of automatic motor testing.

-

- PC Compatible

- Single Three Phase Stators

- Up to 6-wire Connection

- High Accuracy 4-terminal

- Resistance Measurement

- Resistance Balance Test

- Inductance Measurement

- Flash Tests up to 3000V

- Field Rotation Check

Key Benefits

PC - Based System - the stator test unit

is based on a the latest PC with colour monitor display. This allows

full operator information, and menu selectable testing against part

number for any type of stator up to 6 wire connection. Test limits

may be programmed, and results printed. Software calibration is

included.

Safety Guarded System - a well proven

safety system allows fast connection to each winding, and includes

an integral flash test of up to 3000V between windings, and winding

to frame, as part of the automatic sequence.

Solid State Field Check - a solid state

fixed probe enables a check to be made of correct field rotation

as a part of the automatic sequence, for both single and three phase

stators

Full documentation - the equipment is

supplied with full Operator and Service Manuals, spares lists and

maintenance wiring diagrams

|

|

|

| Examples

of Equipment Supplied |

Test Equipment

Capabilities

TQC combines extensive experience with a modular

approach. The best modern data capture methods and proven software

techniques are engineered into your production environment to provide

reliable and easily maintainable equipment.

| Speed

|

|

Noise

and vibration |

| Torque

|

|

Distance

and rotation |

| Voltage

|

|

Inductance and capacitance |

| Current |

|

Frequency |

| Resistance |

|

Power |

| Flow |

|

Pressure |

| Temperature |

|

Force |

|